- Overview

- Product Description

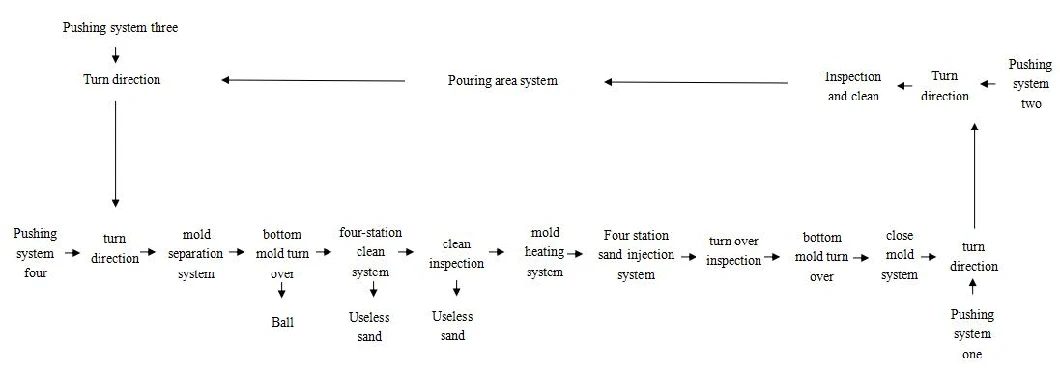

- Flow Diagram

- Detailed Photos

- Certifications

- Our Advantages

- Our Costomers

- Installation Instructions

- After Sales Service

Basic Info.

Packaging & Delivery

Product Description

| Products | Auto parts, small and medium parts, such as Grinding ball, wheel hub, brake drum, water meter case, crankshaft and various discs. |

| Grinding balls,Ф40-Ф130 chromium series alloy cast ball, CADI austempered ductile iron ball | |

| Power supply/voltage | 380V/415V/440V |

| Powder consumption | 100KW |

| Occupied area | 26m*8m (specific size can also be designed according to the area of workshop) |

| Operators | 4 |

| Mold quantity | 75 sets in total mold station |

| Required workshop temperature | 15ºC ~ 50ºC |

| Type of coated sand | Phenolic resin sand |

| Pouring method | Tiltable pouring machine |

| Remote assistance | This production line has remote assistance fuction, which can remotely guide opration to help conveniently and quickly solve problems. |

Analysis of mold action sequence:

mold separation system(up and bottom mold) → scrabble ball → bottom mold turnover → four-station clean system → clean inspection → mold heating system → four-station sand injection system → turn over inspection → bottom mold turnover →close mold system

1. Small occupied area: The production line with an annual output of 10,000 tons covers an area of about 300 m2.

2. Less labors: There are 4 permanent jobs in the production line.

3. Low energy consumption: The power of the whole production line is less than 100kw.

4. The qualified rates of products can reach more than 98%.

5. The equipment adapts to many products, and one production line can exchange different molds to produce different products and reduce investment.

6. The sand coated iron mold production line can be equipped with various forms of pouring to suit different products.

We support with totally installation services and training on site.

These picture was taken by our technician who service, for SCAW Limited provide the total installation and operation.

Accessories: circuit diagram, operating instructions, equipment handover list, equipment acceptance sheet.

Receive the service phone or fax 2 hours to make feedback, if you need to go to the site service, within 72 hours to arrive at the site service(domestic); Foreign countries according to the actual situation of communication after decision.

In the warranty period if occur the quality problem of parts, Party B provide free service, If the problem is caused by Party A's improper use, Party A only bear the cost of materials, Party B provide lifelong maintenance.